Do you have a Machinery need? CALL US!

Xavier Technologies

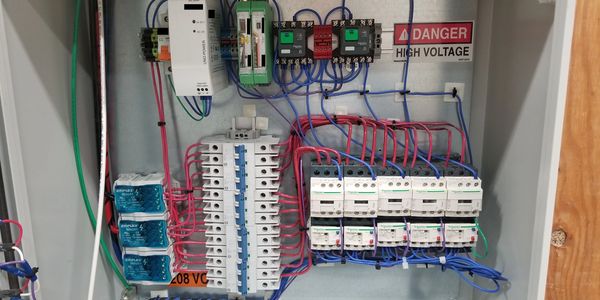

Machine Control Interlock System

Xavier Technologies offers system interlocks that work in conjunction with either or both dust collection systems and Fire alarm systems. These machinery interlocks safely disable manufacturing machinery when a dust collection system is off or malfunctions or when a facility has a fire alarm.

This type of control system where the (Control Voltage/Emergency Circuits) are interrupted is preferred since automated machines like CNC’s will go into a controlled emergency stop rather then a free fall coast that can cause both injuries to personnel and damage machinery, Especially Servo drives and PLC’s compared to a full voltage shut down/power stoppage which occurs in a Shunted Breaker control design.

Having Problems Passing Fire Code?

These interlocks are required per NFPA fire codes that pertain to dust collection systems in the manufacturing sector or at the request of a local jurisdiction.

Per NFPA 664 §8.2.2.1.4, dust collection systems shall be in operation whenever equipment connected to the system for the control of fugitive dust is processing wood stock. Therefore, the system design must

incorporate interlocks configured such that any action resulting in the shutdown of the dust collection

system will prevent the operation of process equipment connected to the dust collection system.

How Does It Work?

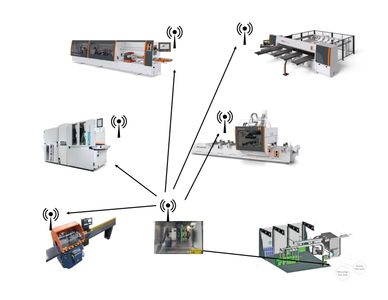

Our systems use either a 2.4 Ghz radio interface system or we offer a 900 Mhz option for very large areas. They can be installed into machinery control cabinets or as standalone’s that are attached to a machine within a Nema 4 rated enclosure.

The radio system is a Frequency hopping technology, so the system always looks for the best channels and is highly resistive to radio interference allowing for a very stable and reliable system.

Since these modules are wired into the machines and control the (Control Voltage/Emergency Circuits) on the machine. They can be easily moved with the machine when restructuring a manufacturing floor. Additional units can be added with ease since there is no interfacing with the buildings structure i.e. no control wires running through building conduit.

Also, Installation costs are less compared to a hard-wired control system that uses conduit and control contactors at each machine. And because this uses a single base station and machine remote modules flexibility is absolute compared to a hard-wired system.

All components are UL listed.